Confirm that the attenuator contains the minimum volume 200mm wide x 100mm high x 200mm long

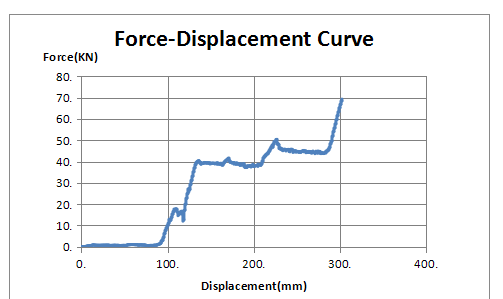

Figure 1: Force-Displacement Curve (dynamic tests must show displacement during collision and after the point v=0 and until force becomes = 0)

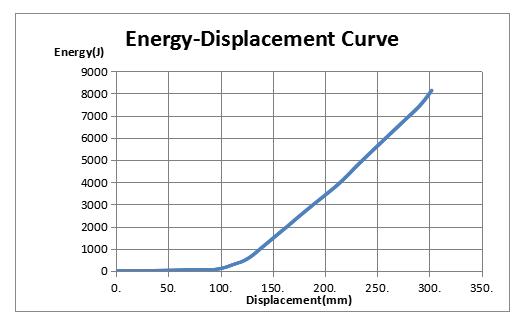

Figure 2: Energy-Displacement Curve (dynamic tests must show displacement during collision and after v=0)

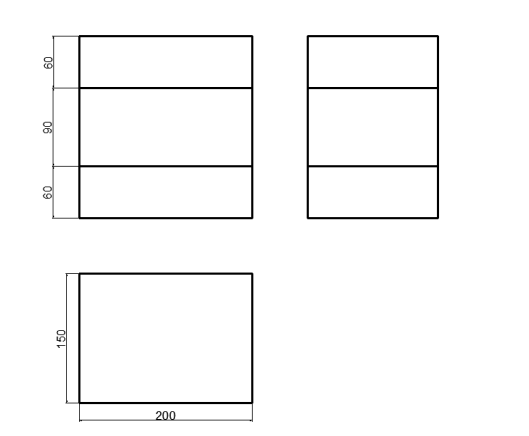

Figure5: The size of the impact attenuator

Length (fore/aft direction): 210 mm (>=200mm)

Width (lateral direction): 200 mm (>=200mm)

Height (vertical direction): 150 mm (>=100mm)

Attenuator is at least 200mm wide by 100mm high for at least 200mm: Yes

This size if the impact attenuator designed by Zhangjiagang Jianglian Precision Machinery Co.,Ltd