© 2016 Zhangjiagang Jianglian Precision Machinery Co.,Ltd All rights reserved. Designed by wonder-tech

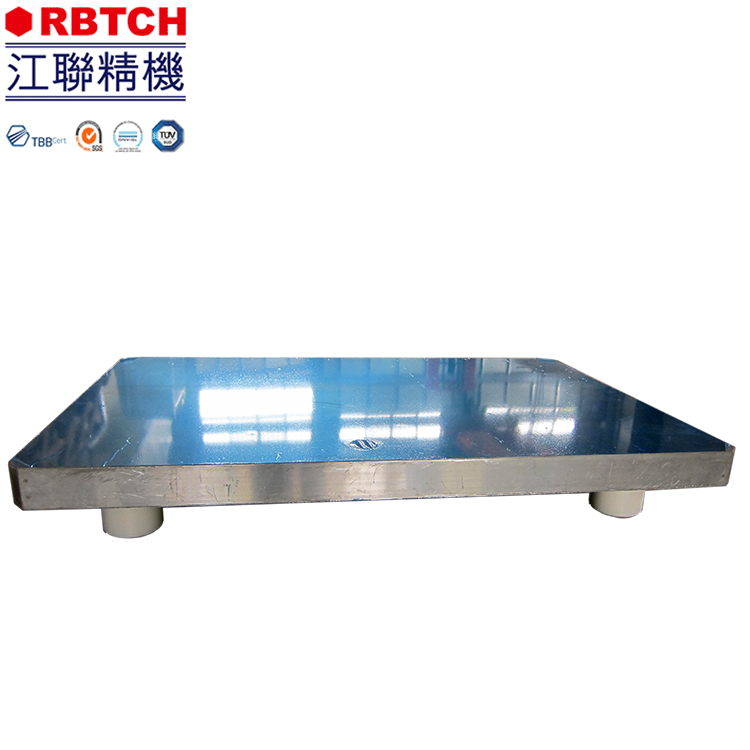

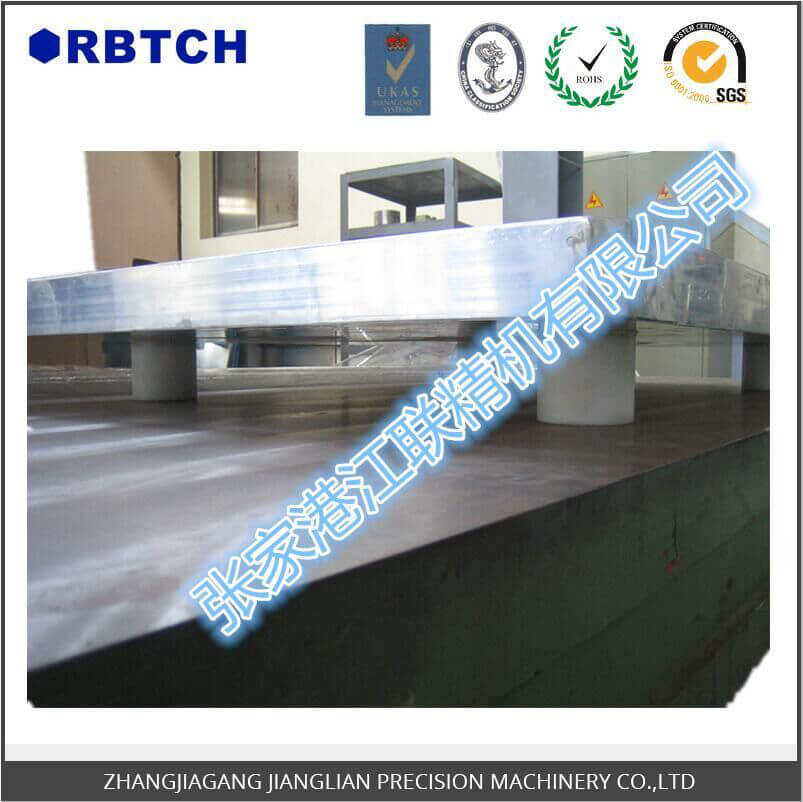

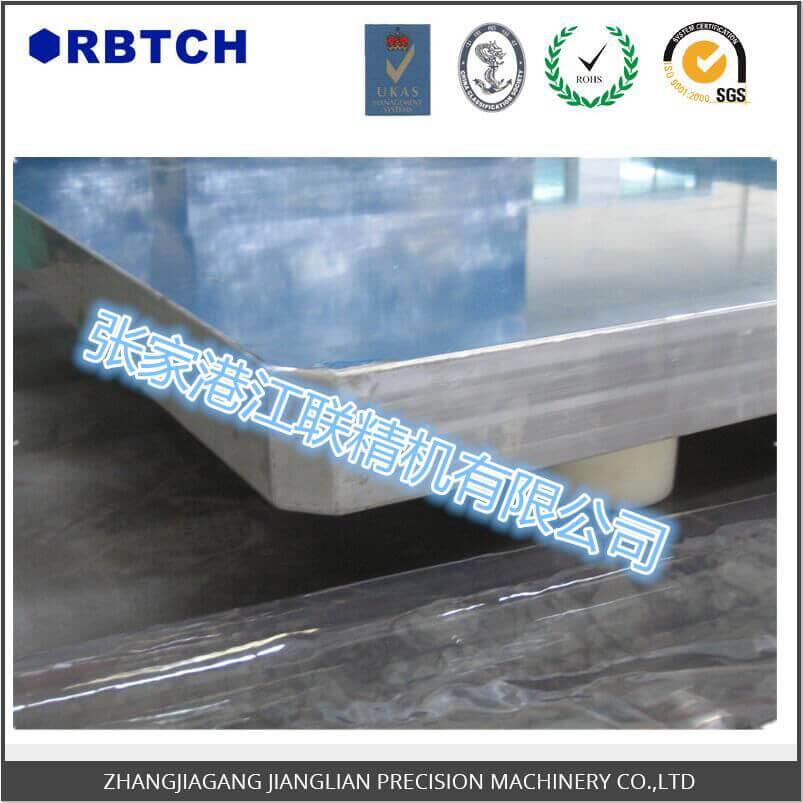

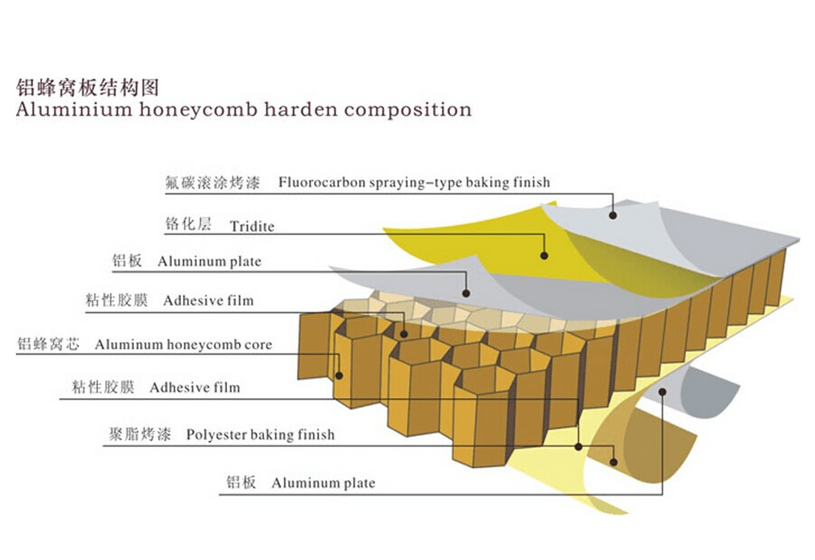

Honeycomb Panel:

Honeycomb panel:aviation,aerospace materials in civil construction,vehicles,ships and other areas of decorative applications.The panel's main selection of high quality sheet material,the top sheet thickness of 0.3-1.5mm The board select PVDF with paint roller or resistance to high temperature paint,bottem sheet thickness of 0.3-1.5mm Poly Ester roller board,the core material with hexagonal 3003H18 aluminum honeycomb core,aluminum foil thickness 0.04-0.08mm,cell size 2-15mm,the total thickness of 5-500mm.

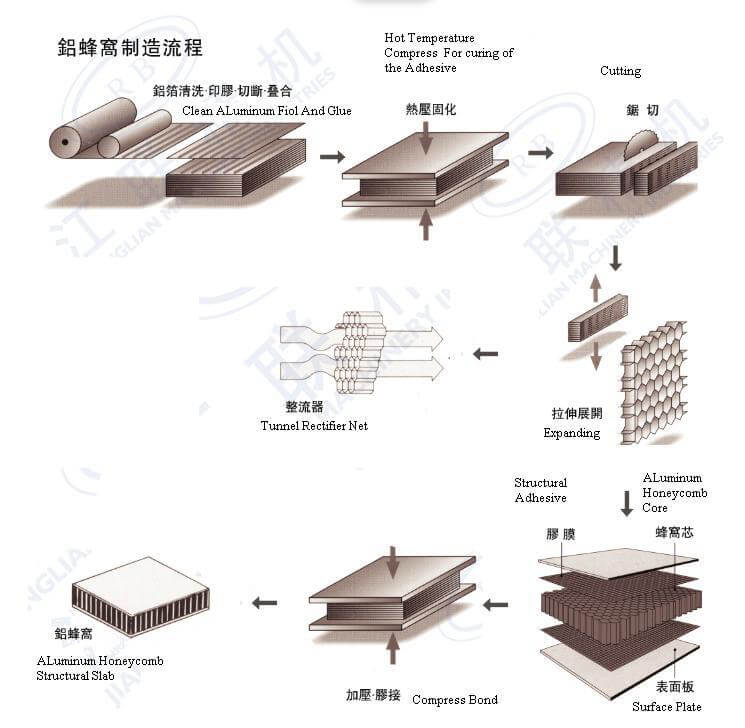

Production Mode:

Technologies:The main use if three ways,a continuous roll forming,hot forming single or multiple piece,and at room tempreature adhensive forming.

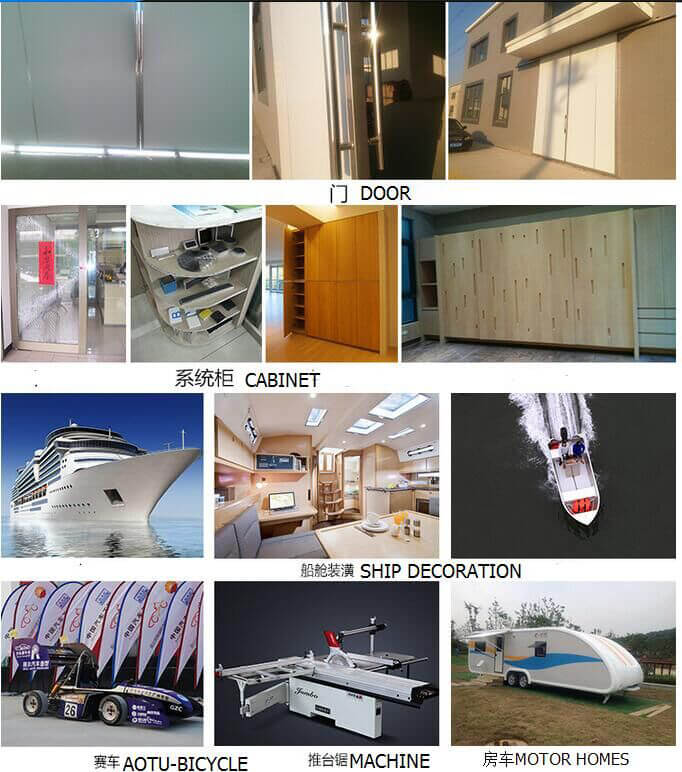

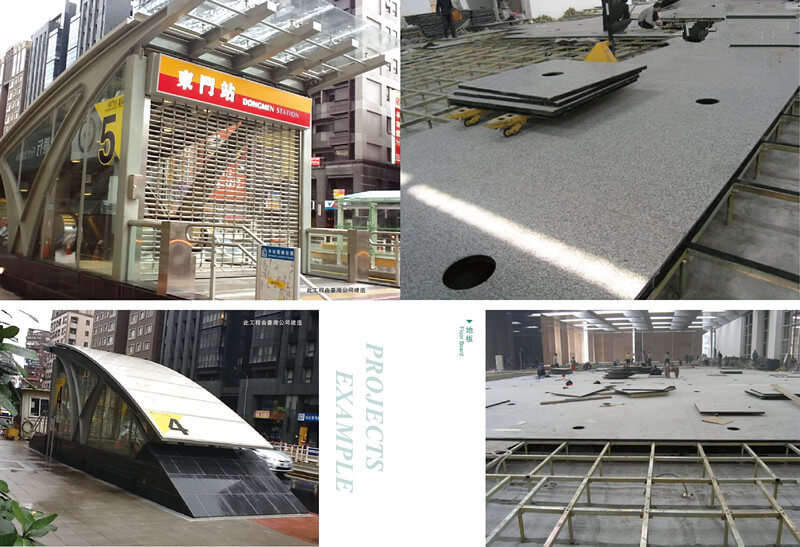

Application areas:

(1)Building roofs, walls, ceiling ,the elevator wall, floor

(2) vehicle cabs, car end of the car top

(3) The advertising decorative display card production, cut off the board

(4) Whiteboard

(5) high-precision electronic platform

(6) electronic equipment load plate

Technical information :

Density: 3.6 ~ 7.2 kg/m2,

Flatness <0.5mm/m2

Board body thermal resistance 0.026m2.k / w

0.104-0.130W/MK equivalent thermal conductivity, energy absorption capacity of the150-3500KJ / M

Sound reduction 29dB

Fire rating of 2006-A2 (GB 8 624)

Elastic modulus of 4 × 104MN/m2

Bending tensile strength ≥ 83MN / m

Shear strength 2Mpa

Stiffness (kN/m2) 1.0 ~ 23.0

Applicable to the environment: -40 to +80 degrees Celsius

Paint the useful life: 20 years warranty

Main Characteristics:

(1)Panel with 70% of the pvdf paint,weathering Resistance,A self -cleaning Ability,long service life.

(2)For ambient temperature-40 -+80 the various regional

(3)Environment-friendly materials, all metal construciton ,100% recyclable

(4)Plane roughness

(5)High Intensity

(6)Stiffness

(7)Lighy weight:the same thickness,with an area weight of 1/5 of wood ,Glass,1/7 aluminum

(8)Fire Performance:>B1 level

(9)Sound insulation:the amount of air noise 29db

(10)Good insulation :Thermal conductivity of 0.16w/(M.K)

Manufacturing technique

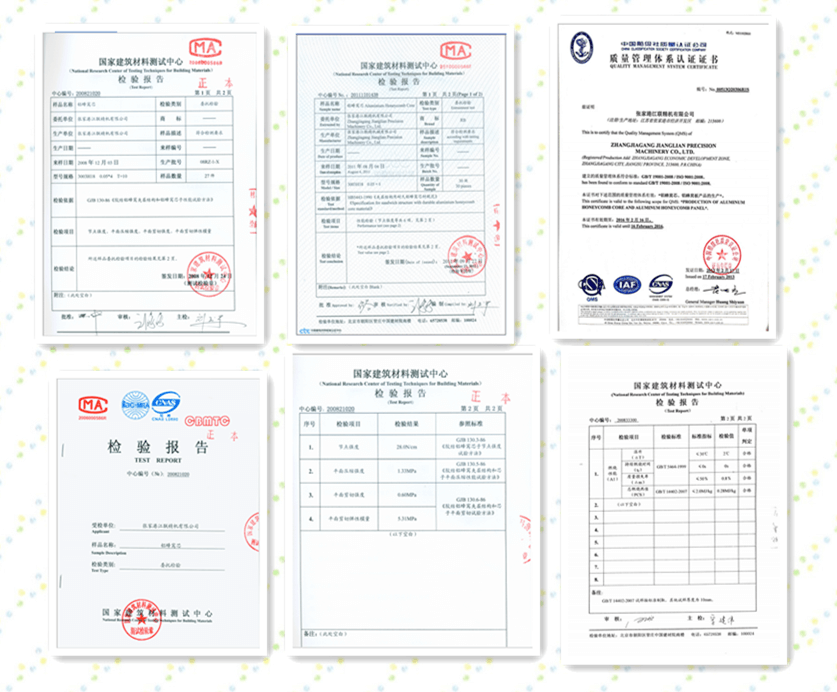

Certification

Project Example

application